I am a previous Psychology Undergraduate who held a keen focus on organisational psychology, this led me to the subject of Human Factors and Ergonomics. I held initial contacts with a car manufacturing company to complete a collaborative project, where they proposed the issue of evaluating the perceptions towards Ergonomics in their industry. To approach this problem a series of interviews with ergonomists themselves and engineers they work closely was conducted to establish several reoccurring themes surrounding Ergonomic integration.

Major project

Exploring the barriers and enablers of ergonomic integration: A car manufacturing industry case study

Integrating Ergonomics into car manufacturing and production

Previous research has focused on what processes are in place that demonstrate ergonomic integration for improving operator health and safety, reducing time-loss incidents and improving product quality. However, there is little known about how these processes are embedded into an organisation and the challenges that come with doing so. The following investigation looks to identify the process of ergonomic integration, whilst highlighting improvement strategies to enhance this process.

Project Aims

To identify the unique barriers and facilitators of ergonomic integration relevant to the car manufacturing industry, which will be done at a number of levels across an organisation by looking holistically at attitudes and behaviours towards ergonomics, identifying improvement strategies for integration implemented by the ergonomics team and comparing the different approaches taken across the three companies whilst considering the challenges they face.

Methods

Participants:

Six participants were recruited across three different car manufacturing companies, occupational roles of the participants consisted of ergonomists, engineers and safety representatives.

Sampling strategy:

Purposive sampling strategy to provide a holistic representation of the industry.

Data collection:

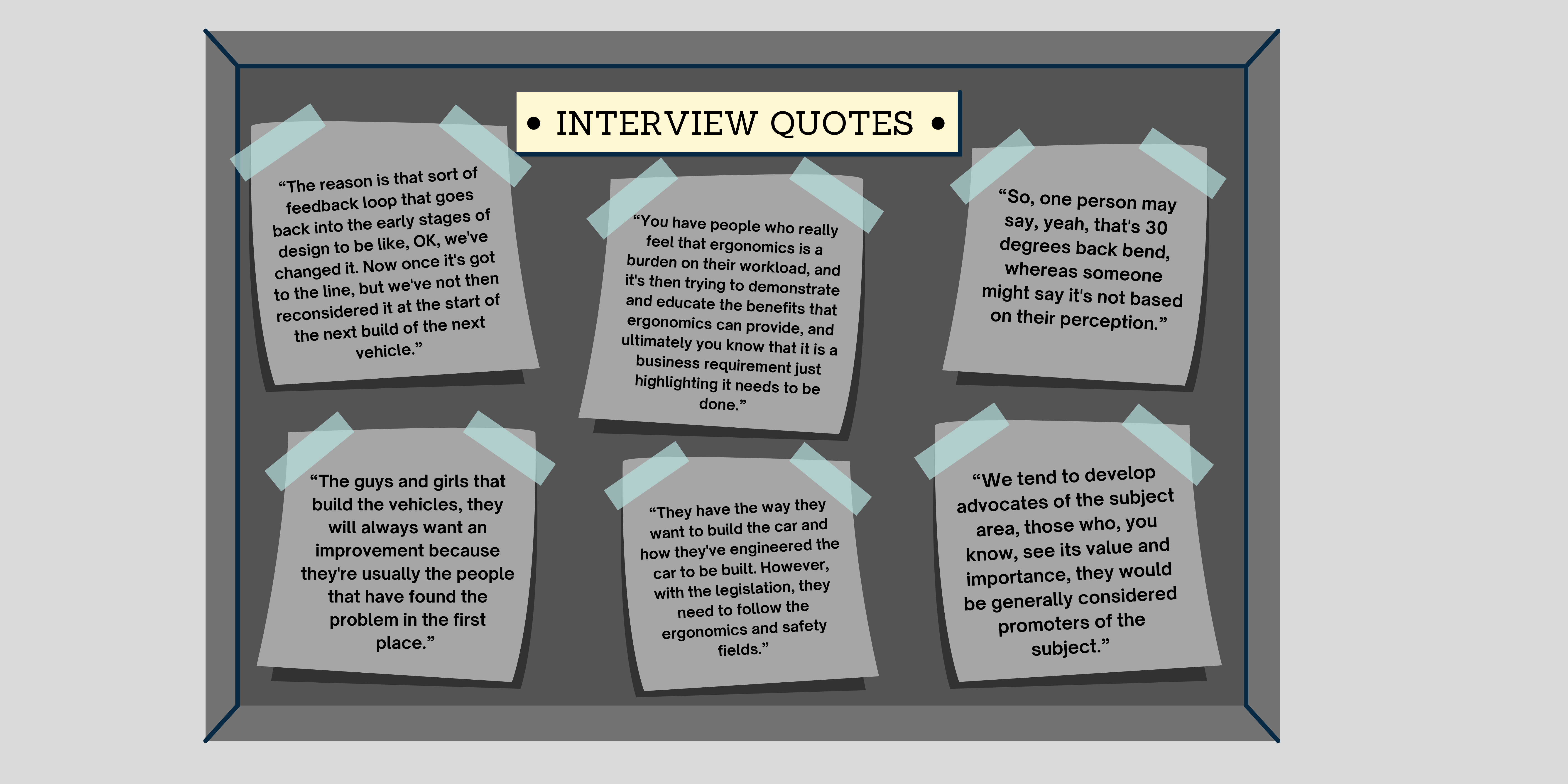

Semi-structured interviews consisting of a series of questions surrounding cultural attitudes towards ergonomics, the reasoning for rejecting ergonomic recommendations and future challenges for the subject within the industry.

Data analysis:

Thematic analysis via 'NVivo 12' to identify initial codes which contribute towards themes and sub-themes, these findings were then cross-examined across the three companies.

Results 1

Cost and resources, a lack of knowledge, and negative perceptions were prominent barriers to integration. Top-down integration, visibility of the subject, simplifying methods to improve accessibility, and communication were reoccurring improvement strategies for ergonomic integration. The unique issues related to the industry that had not been previously found consisted of ergonomists not having the resources to review all ergonomic issues. Furthermore, there was a consistent issue of ambiguity within the posture assessment tools provided for risk assessors. To improve this, assessment methods were adapted internally to suit the environment they are applied to.

Results 2

A table of the themes and sub-themes constructed from the data analysis, demonstrating the breadth of detail obtained from the interview schedule. The most unique findings originating from the industry can be found in the 'organisational factors' sections of the table.

Discussion

This investigation shed light on the unique barriers and improvement strategies for ergonomic integration used in the car manufacturing industry, different approaches were needed in comparison to the nuclear and defence industries which have seen extensive research in this field. More work still needs to be done to improve the perception that ergonomics can improve product quality even in the latter stages of design, as well as improved assembly line health and safety, especially with the introduction of new technology which includes exoskeletons. Future work should provide a longitudinal approach to this subject, allowing the review of perceptions changing over time and evaluating improvement strategies.

Aaron McGuinness

Major project

Exploring the barriers and enablers of ergonomic integration: A car manufacturing industry case study